PCB Board Preparation

Figure showing steps involved in PCB board

preparation.

Step 1

Step 2

Step 3

Step 4

Step 5

For

printing of PCB design layouts to be done, first the plain PCB board of

matching size to the design layouts need to be prepared following the steps

shown in figure above.

Step

1 shows cutting of PCB design layouts from the printed OHP paper. In step 2,

the plain PCB board are being cut following the size of cut out design from OHP

sheet. Step 3 is about polishing the copper surface of plain PCB board to

remove the oxide layer, followed by wiping of oxide dust with tissue paper and

then with thinner as in step 4 and 5 respectively.

Ironing Method

Figure showing steps involved in printing PCB layout

designed onto PCB board prepared.

Step 1

Step 2

Step 3

After

preparing plain PCB board of matching size, printing of PCB design layouts on

plain PCB can now be done following steps shown in figure above. First, the

printed side of the OHP sheet need to be placed onto the copper surface of PCB

board. Then, with the board and OHP sheet placed under a piece of white paper,

the ironing can be done for printing process. Lastly, if the printing does not

seem to be perfect with some of the dark line not appearing, then a permanent

marker needs to be used to draw onto it.

Etching

Etching

is a process of removing unwanted copper part on the PCB board designed,

leaving only the copper part covered with permanent marker. To start etching

process, the final product after the printing process as shown in step 1 of

figure below need to be immersed in a container containing the etching acid

which is dark brown in colour, as in step 2 below. The container need to be

shaken gently and constantly for the acid to move around the surface of the

copper layer of the board for more effective and rapid etching process. After

etching the unwanted copper, now it can be clearly seen as in step 3 below that

only the permanent marker lines are left over. In step 3, the board was cleaned

with plain water to remove the acid layer.

Figure showing steps involved in etching process.

Step 1

Step 2

Step 3

Removing Marker Layer

Following

after the etching process are process of removing permanent marker layer

covering the copper layer. The permanent marker is removed using thinner by

wiping with sponge as in figure a below. The result is PCB board with shiny

copper design layout on top of it as in figure b below.

Figure showing process of removing permanent marker on

PCB layout.

a

b

Checking Connectivity

When

the multimeter touches connected copper lines, it gives reading of “0” as in

figure b below. If the copper lines are disconnected, it gives reading of “1”

as in figure a below.

Figure showing process of checking connectivity for

the PCB layout.

a

b

Drilling

Figure

showing PCB hand drill used in the project.

Figure

showing drilling process.

Step 1

Step 2

Drilling

of PCB need to be done carefully to ensure the PCB layouts are not damaged or

disconnected. For that, the hand drill had to be held firmly and be pointed to

the exact drilling point without shacking when started to drill as shown in

step 1. The drilled hole need to be checked and cleaned from the board dust

produced during drilling process as to prevent the drilled hole being blocked as

shown in step 2 figure.

Completion To Hardware Development

Figure showing PCB circuits board prepared for the

component placement and soldering.

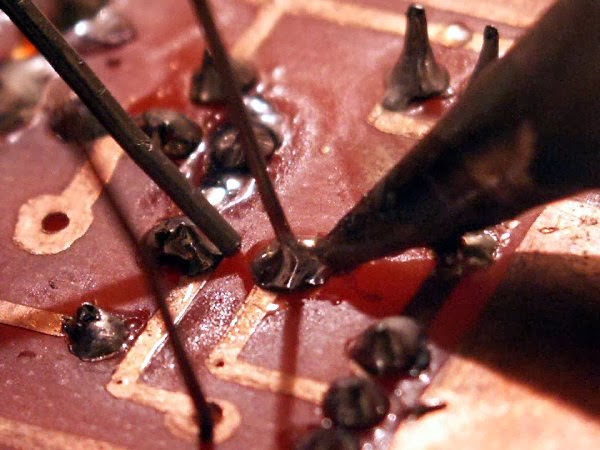

Soldering

Figure showing soldering process after the component

placement.

a

b

To

start soldering process, several tools and material have to be prepared first,

such as soldering iron, solder lead, solder paste, sucker, and wet cloth as

shown in figure a above. Before start soldering, the method need to be

understand first in order to produce good soldering work. When soldering, first

the copper pad surrounding the component leg need to be heated. Then, solder

lead need to be touched on to the heated pad and let it melt to stick to the

component leg perfectly as shown in figure b above.

No comments:

Post a Comment